Mixer wear-resistant Feed Auger Blade

Mixer wear-resistant Feed Auger Blade offers enhanced durability, reducing wear in heavy-duty mixing applications for extended service life.

Feed Ribbon Blade: Features and Benefits

Optimized Material Feeding

The feed ribbon blade is meticulously designed to enhance the efficiency of material delivery into the concrete mixer drum. Its spiral structure allows for smooth, continuous material flow, ensuring consistent mixing performance while preventing issues like material clumping or uneven distribution. For even better results, feed ribbon blades manufacturing focuses on creating blades that maximize the flow and transfer of materials, while high-efficiency feed ribbon blades provide an advanced solution for smoother operation.

Built for Durability

Constructed with high-quality, wear-resistant materials, the feed ribbon blade is designed to endure the rigorous conditions of concrete mixing. Its solid construction resists wear, minimizing the need for frequent replacements and extending its overall service life. Both mixer feed ribbon blades and high-efficiency feed ribbon blades are built to withstand demanding environments. The process of feed ribbon blades manufacturing ensures each blade meets durability standards for consistent performance, even under the toughest conditions.

Improved Mixing Consistency

With the feed ribbon blade, material distribution inside the mixer is always even, ensuring a uniform blend of aggregates, water, and cement. This leads to the production of higher-quality concrete with improved consistency. The precision offered by feed ribbon blades manufacturing further refines mixing performance, and high-efficiency feed ribbon blades are specifically crafted to enhance the efficiency and consistency of the mixing process.

Corrosion and Wear Resistance

Designed to perform under tough conditions, the feed ribbon blade is resistant to corrosion and abrasion, which ensures a long operational life. It can endure exposure to moisture, harsh chemicals, and abrasive materials without compromising on performance. Mixer feed ribbon blades are specifically designed to excel in these environments, and high-efficiency feed ribbon blades are built with even more resistance to wear through the advanced techniques of feed ribbon blades manufacturing.

Versatile Applications of Feed Ribbon Blade

The feed ribbon blade is suitable for:

Concrete batching plants, where consistent and efficient material feeding is critical for optimal concrete production.

Ready-mix concrete plants, where reliable material flow ensures smooth mixing and uniform consistency.

Construction sites, where quick material delivery is essential to meet production deadlines.

Why Choose Our Feed Ribbon Blade?

Large-Scale Production Capabilities

Our facilities are capable of producing high volumes of feed ribbon blades to fulfill bulk orders. Thanks to our advanced feed ribbon blades manufacturing, we can consistently deliver large orders without sacrificing quality. Whether you need mixer feed ribbon blades or high-efficiency feed ribbon blades, we ensure timely and efficient production.

Dependable Stock Availability

We maintain an extensive inventory to guarantee the quick dispatch of mixer feed ribbon blades and high-efficiency feed ribbon blades, ensuring you can avoid delays in your operations. Our feed ribbon blades manufacturing process ensures that we always have the blades you need in stock and ready for immediate delivery.

Global Reach

Concrete producers around the world trust our feed ribbon blades for their reliability and performance. We offer both mixer feed ribbon blades and high-efficiency feed ribbon blades, each manufactured to meet the highest standards, catering to a variety of operational needs.

Descriptions

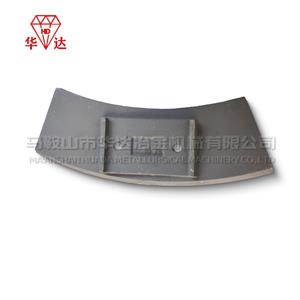

Sturdy Construction for Long-Lasting Performance

The feed ribbon blade is made from durable, wear-resistant materials, designed to withstand the demanding conditions of concrete mixing. Whether you need mixer feed ribbon blades or high-efficiency feed ribbon blades, each blade is crafted using feed ribbon blades manufacturing techniques to ensure excellent performance over time.

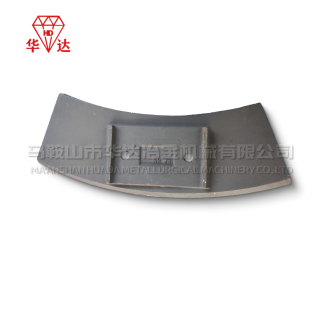

Feed Ribbon Blade in Operation

Watch as the feed ribbon blade works inside the mixer, continuously transferring materials into the drum for efficient and high-quality mixing. Mixer feed ribbon blades enhance the material flow, and high-efficiency feed ribbon blades further optimize the mixing process. With advanced feed ribbon blades manufacturing, each blade contributes to smoother operation and better overall results.