High-Performance Crusher Mantles Boost Productivity and Reduce Maintenance in Mining and Quarrying Operations

In the mining, quarrying, and aggregate industries, the efficiency and reliability of crushing equipment directly affect production output and operating costs. Among the key wear components in cone crushers, the crusher mantle plays a crucial role in ensuring consistent crushing performance, optimal particle size, and prolonged equipment lifespan. Recent advancements in material science and manufacturing processes are driving a new generation of high-performance crusher mantles that deliver superior durability and efficiency.

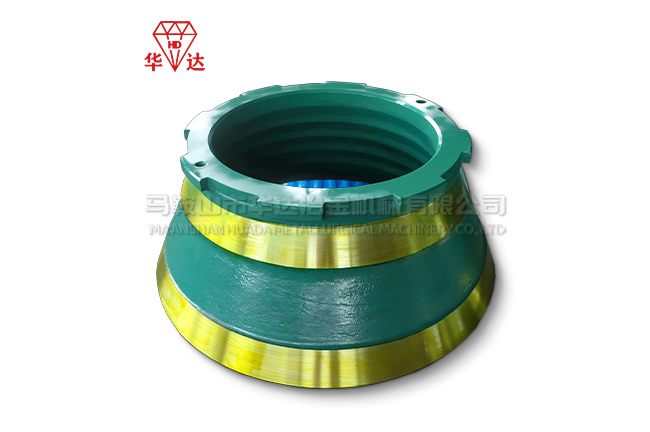

The crusher mantle is the moving component inside a cone crusher that works in conjunction with the fixed concave liner to crush rock and ore. As the mantle gyrates within the crusher chamber, it exerts compressive force on the material, reducing it to the desired size. Due to continuous exposure to abrasive rock and intense crushing forces, the mantle is subject to significant wear, making material quality and design precision critical factors in its performance.

Modern crusher mantles are manufactured using high-manganese steel, manganese-chrome alloys, and in some cases, tungsten carbide-enhanced wear surfaces. High-manganese steel is particularly valued for its work-hardening properties, becoming harder and more wear-resistant as it is used. These advanced materials significantly extend service life, reducing the frequency of replacements and minimizing costly downtime.

In addition to material improvements, manufacturers are optimizing mantle geometry and profile design to enhance crushing efficiency. The right profile not only improves throughput but also ensures a more uniform particle size distribution, reducing the need for downstream processing. Advanced computer-aided engineering (CAE) tools and wear simulations are now being used to design mantles with better load distribution, reduced localized wear, and improved material flow through the crushing chamber.

One of the most notable developments in the industry is the introduction of modular mantle systems. These allow for faster, easier replacements without complete dismantling of the crusher, a major advantage in operations where time is critical. Some designs even feature replaceable wear segments, so operators can swap out only the most worn sections rather than the entire mantle, significantly reducing maintenance costs.

The operational benefits of using high-quality crusher mantles extend beyond wear life. A well-designed mantle helps maintain consistent crusher settings, reduces energy consumption, and ensures optimal utilization of crushing power. This results in better overall plant efficiency, improved production rates, and lower cost per ton of processed material.

As global demand for minerals, aggregates, and construction materials continues to rise, the role of durable and efficient wear parts like the crusher mantle becomes increasingly important. With ongoing innovation in metallurgy, manufacturing, and design, the latest generation of crusher mantles is set to help mining and quarrying operations achieve higher productivity, lower maintenance costs, and more sustainable operations.