Next-Generation Wear-Resistant Liners Boost Equipment Longevity and Operational Performance Across Industries

In industries such as mining, cement production, power generation, steelmaking, and bulk material handling, wear-resistant liners have become an indispensable component for extending equipment lifespan and optimizing operational performance. As production demands intensify and environmental conditions become more challenging, manufacturers are investing heavily in advanced liner technologies that provide superior abrasion resistance, reduce maintenance costs, and improve overall efficiency.

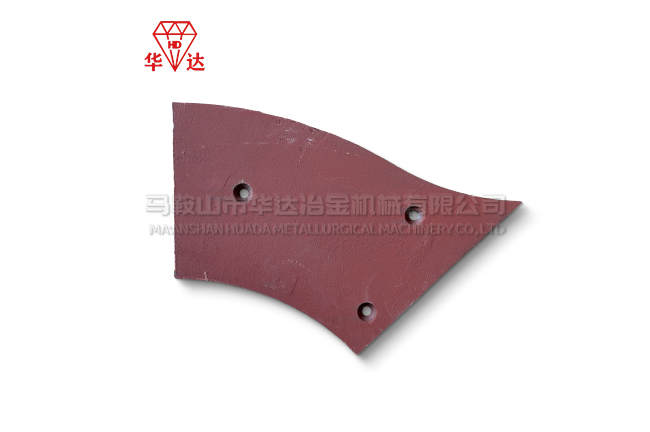

A wear-resistant liner serves as a protective layer inside machinery and material handling equipment. Its primary purpose is to absorb the abrasive and impact forces generated by hard materials such as ore, coal, clinker, aggregates, and other bulk solids. By taking the brunt of this wear, liners prevent costly damage to the underlying structural components, effectively safeguarding key assets such as chutes, hoppers, mixing drums, crushers, and mill shells.

The choice of material for wear liners is critical to their performance. Modern designs incorporate high-manganese steel, chromium-rich white iron, tungsten carbide coatings, and engineered ceramic composites. These materials are engineered to offer exceptional hardness, impact resistance, and corrosion protection. For example, chromium-rich white iron is renowned for its extreme abrasion resistance, while high-manganese steel provides excellent work-hardening properties, making it ideal for high-impact environments.

Recent advancements in wear liner technology also include the application of composite structures, combining metal backings with ceramic or polymer wear surfaces. This hybrid approach offers both structural strength and extended wear life, enabling the liners to perform optimally under both high-impact and high-abrasion conditions. In addition, manufacturers are employing precision CNC machining and laser hardening techniques to improve dimensional accuracy and surface properties, ensuring better fit and performance in critical equipment.

Another key innovation is the rise of modular wear liner systems. Instead of replacing an entire large liner, maintenance teams can now change individual panels or segments, significantly reducing downtime and material waste. This modular approach is especially beneficial for industries operating in remote or high-production environments, where equipment stoppages can translate into substantial financial losses.

The operational benefits of wear-resistant liners extend beyond just equipment protection. By maintaining smoother internal surfaces in chutes, conveyors, and hoppers, liners help reduce material buildup and blockages, improving material flow efficiency. This results in more consistent throughput, lower energy consumption, and better product quality. In processing plants, where even minor flow disruptions can lead to costly slowdowns, the role of a properly designed liner is crucial.

With sustainability becoming a priority across industrial sectors, wear-resistant liners are also contributing to greener operations. Longer-lasting liners mean fewer replacements, reduced material usage, and less waste, aligning with environmental regulations and corporate ESG goals. Some manufacturers are now experimenting with recyclable liner materials and low-carbon production processes, further reducing the environmental footprint of these essential components.

Market analysts predict that the demand for high-performance wear liners will continue to grow, driven by the need for more reliable equipment in high-intensity applications. As global infrastructure projects expand and industries push for greater efficiency, wear-resistant liners are expected to remain a cornerstone in heavy equipment maintenance strategies.

Ultimately, the evolution of wear-resistant liner technology is enabling industries to achieve a delicate balance between productivity, cost-efficiency, and sustainability. Whether protecting the inside of a mining crusher, extending the service life of a cement kiln, or maintaining smooth operation in a coal chute, the humble liner plays a vital role in keeping the world’s heavy industries running at peak performance.