Wear Rings for Mining Equipment See Rising Demand Amid Focus on Durability and Efficiency

As the global mining industry continues to prioritize efficiency and cost control, wear rings — critical components used in various mining machinery — are gaining attention for their role in enhancing equipment longevity and minimizing downtime.

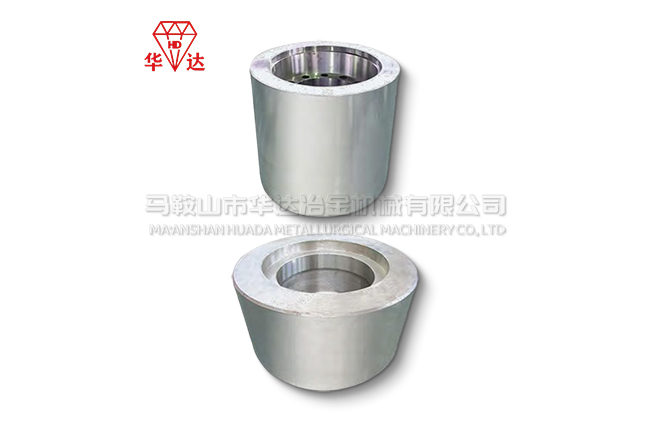

Wear rings, also known as abrasion-resistant rings or sealing rings, are commonly used in crushers, slurry pumps, and other high-wear mining applications. These components serve as protective barriers, reducing metal-on-metal contact and absorbing abrasive forces that would otherwise damage essential machinery parts.

In response to harsh operating conditions found in open-pit and underground mines, manufacturers are now developing wear rings using advanced materials such as high-chromium cast iron, tungsten carbide, and ceramic composites. These materials provide excellent resistance to erosion, corrosion, and high-impact forces — ensuring longer service life even in the most demanding environments.

Innovations in manufacturing techniques, including precision casting and CNC machining, have improved the dimensional accuracy of wear rings, which helps ensure tighter sealing, better alignment, and more consistent performance in mining operations. Many companies are also investing in modular and easily replaceable wear ring designs to reduce maintenance times and improve operational efficiency.

With increasing production pressures and stricter safety regulations, mining operators are expected to continue investing in high-performance wear parts. As a result, the market for wear rings is projected to expand steadily over the coming years, especially in regions rich in mineral resources such as South America, Africa, and Southeast Asia.

These advancements underscore the vital role of seemingly small components in driving the broader efficiency and reliability of large-scale mining operations.

In 2002, the first year of Huada, Huada has been moving forward for more than twenty years. Huada has not forgotten its original intention and has been forging ahead, always practicing the business philosophy of "creating precision quality, customer satisfaction first, guiding value creation, and continuously deepening reform". Vigorously promote the core values of the enterprise of "integrity and pragmatism, unity and friendship, continuous innovation, and willingness to contribute". In the fierce market competition, we strive to create an innovative casting and processing enterprise and aspire to become a leading enterprise in the industry.